|

Whatever

the nature of the biogas, the GASWASH process separates

the biogas from its impurities (CO2, H2S, VOC, Siloxanes).

The methane content of biogas increases from 45%

to 98% and can be directly injected into the national

gas distribution network.

The

advantage of our GASWASH process is that it uses

reliable, robust, widely proven technology that

comes directly from the industry. This system adapts

according to the variation of the methane richness

according to the composition of the incoming crude

biogas.

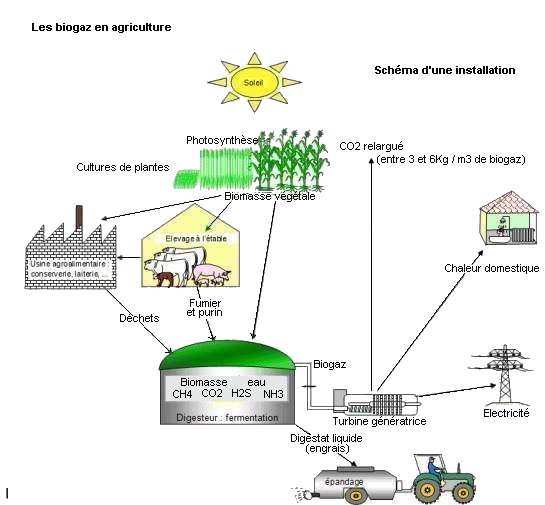

Why methanize our waste ?

Why methanize our waste ?

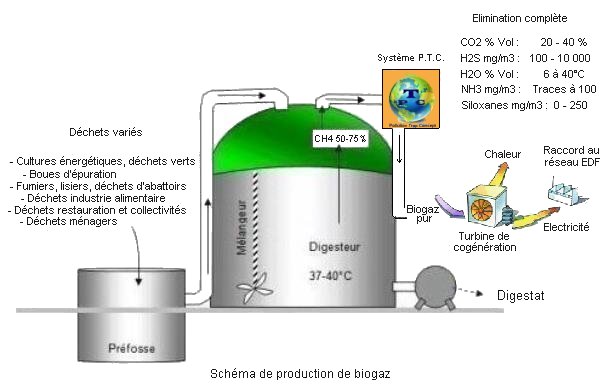

Methanisation,

which is still underutilized to date, appears to

be an answer to the dual issue of waste management

and the development of renewable energies; Not to

mention the fight against greenhouse gases, of which

CO2 is a part.

The

principle of methanization consists in recovering

the organic waste to recover it in the form of biogas

by anaerobic fermentation.

Organic waste can come from agricultural (slurry,

manure), industrial and tertiary (including LPN

waste) or from local authorities (catering waste,

grass clippings ...).

Biogas is composed in particular of methane in variable

proportion, which gives it an energy potential.

This biogas, after purification, is used to produce

electricity and / or heat. It can also be injected

into the gas distribution network, or even used

as a fuel gas.

To

date, the

purification of biogas requires a succession

of operating phases.

The GASWASH process has the advantage of treating

all the undesirable compounds in a single operation.

In

addition to biogas, agricultural methanization allows

the production of a fertilizer, the digestate, which

can be applied (As part of a spreading plan, or

as a standardized product after composting).

The development of methanation is fully in line

with the objectives of the energy transition law

for green growth promulgated on August 18, 2015.

France

wants to develop renewable energies up to 23% of

the energy mix by 2020, with a strong contribution

from biomass to these objectives (wood energy and

methanisation).

Thus, the State sets a target of 1,500 methanizers

in 3 years, and methanisation is at the heart of

the plan Energy Methanization Autonomy Nitrogen

(EMAA) of 29 March 2013 (see

site internet http://agriculture.gouv/Plan-Energie-Methanisation).

It

should be noted that in this configuration, the

biogas is not purified so that it is a source of

olfactory nuisance due to H2S and NH3. On the other

hand, the fermentation CO2 is released to the atmosphere

(greenhouse gases).

The

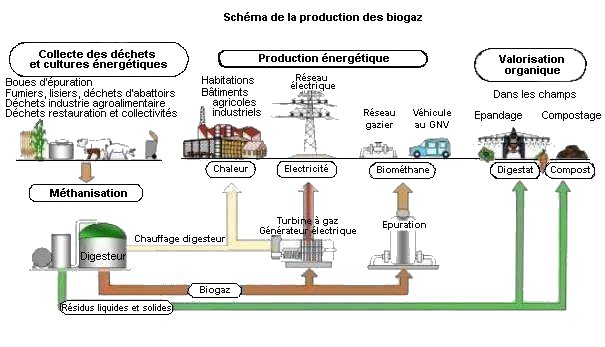

current biogas - biomethane sector

The

current biogas - biomethane sector

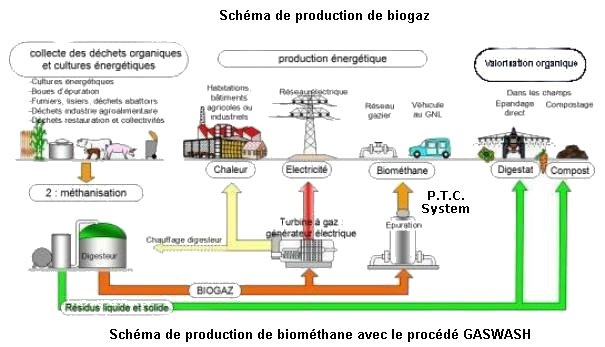

The uses of biomethane are the same as those of

natural gas: domestic hot water, heating, cooking,

industrial needs, etc. One of the relevant valuations

still unrecognized is the valuation of fuel.

The use of biomethane in transport fuels (known

as bioGNV) would reduce greenhouse gas emissions

in this sector.

Furthermore, on the understanding that bioGNV and

NGV (natural gas for vehicles) have the same chemical

composition, gas-fueled vehicles and filling stations

can be supplied with bioGNV without technical modifications.

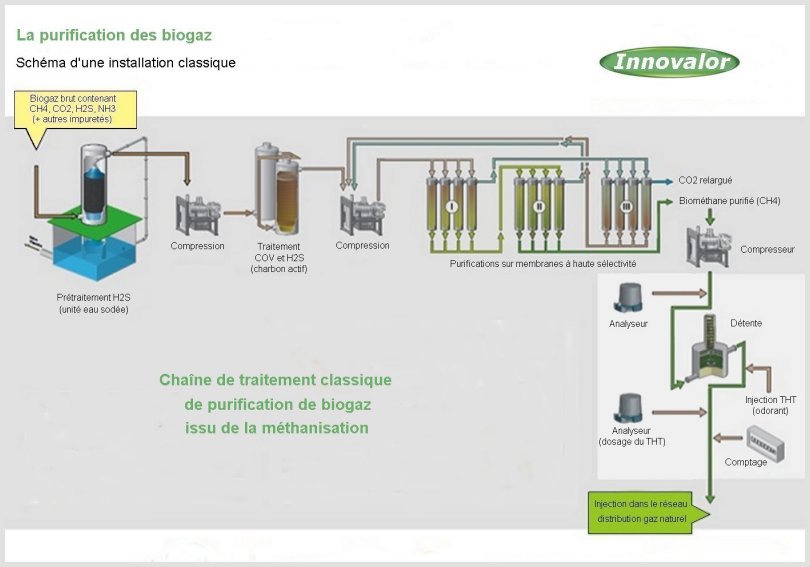

Diagram of the conventional

pathway

The

purification of biogas

The

purification of biogas

To

date, biogas purification is carried out mainly

for the upgrading of biomethane by injection into

natural gas distribution networks of fossil origin.

|

|

The

diagram above shows the complexity of such

a purification plant comprising several treatment

units and it will be noted that the CO 2,

which is momentarily trapped, is released

to the atmosphere. Such facilities represent

a significant investment and operating cost

(eg, activated carbon costs).

Opposite a processing

unit diagram with the GASWASH process

Le

The GASWASH process, which is innovative because

of its simple but particularly effective technology,

has a prominent place among the

current biogas purification techniques.

It is the only one known to completely eliminate

in the same operation and on a single treatment

unit CO2, N2, O2, H2O, H2S, NH3,

Siloxanes,

Organochlorines ou Organofluorines, etc....

|

Actualy, what is the CO2 balance

of a methanisation unit?

Actualy, what is the CO2 balance

of a methanisation unit?

|

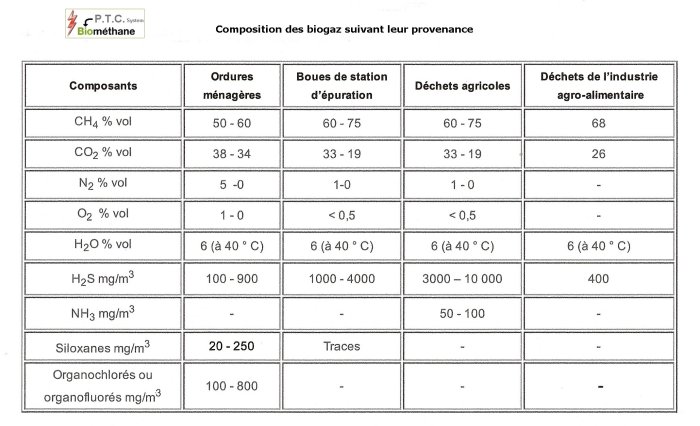

Each m3 of biogas from methanisation has helped

to avoid the release into the atmosphere of

2.3 kg of carbon

dioxide (CO2) responsible for global warming.

A methanisation unit of 2 MW electrical, by

the principle of methanization, thus avoids

the emission of about 9 000 t of CO2 in the

atmosphere. However, it should be borne in

mind that each m3 of biogas produced always

contains between 20 and 40% CO2, ie between

3 kg and 6 kg.

|

|

This carbon dioxide is ultimately released to the

atmosphere, either during purification in biomethane

by competing techniques or in the use of biogas

without purification.

It should be noted that this same methanisation

unit of 2 MW and which consumed about 4 Mm3 of biogas

nevertheless issued.

Between 800 t and 1600 t CO2 in the atmosphere depending

on the nature of the methanated substances. The

composition of the biogas and therefore its impurities

varies according to the nature.

An INERIS report (15/12/2009) mentions concentrations

of carbon oxysulphide (COS) in the range of 0.047

to 0.29 mg/m3 in biogas from the methanisation of

sludge from sewage treatment plants..

Biomethane: Towards a cost

of production finally competitive ?

Biomethane: Towards a cost

of production finally competitive ?

The GASWASH process is the only known technology

to date, making it possible to permanently eliminate

and advantageously recover the CO2 resulting from

methanation in the form of carbonates and which

is recoverable in particular in industry.

It allows the total, sustainable and one-stop capture

of both CO2 and all volatile volatile compounds

(N2, O2, H2O, H2S, NH3, Siloxanes,

Organochlorines or Organofluorés).

The

GASWASH process allows a cost of production of biomethane

3 times cheaper than the competition and thus makes

it possible to reduce the cost difference between

the methane of fossil origin and the biomethane

to incorporate it in the network.

The

GASWASH process: a new innovative process

The

GASWASH process: a new innovative process

The

system for the complete purification of Biogas of

any kind in a single operation and on a single treatment

unit.

| |

|

|

The

recovery of biogas

Composed mainly of methane and carbon dioxide,

biogas is efficiently recovered in biomethane

by purification processes.

This technique, called methanisation, is caused

in digesters, during the treatment of household

refuse, industrial or agricultural waste and

sewage

sludge.

Biogas, resulting from the fermentation of

this waste, is a renewable energy source which,

after purification, can replace natural gas

of fossil origin.

Farmers, industrialists and communities thus

treat their waste while exploiting their energy

and economic potential. The GASWASH purification

solution enables the recovery of all biogas

for injection into the natural gas network,

the production of vehicle fuel (biomethane

gas or liquid) or the production of renewable

hydrogen after biomethane reforming.

The

purification technology using the GASWASH

technique

In order to transform biogas into a substitute

for natural gas, it is necessary to get rid

of all the pollutants.

The GASWASH process proposes a technical solution

that allows biogas producers to efficiently

use biomethane in its process of purification.

The technology used makes it possible to permanently

remove carbon dioxide (recyclable CO2), and

to eliminate in the same operation N2, O2,

H2O, H2S, NH3, Siloxanes,

Organochlorines or Organofluorines.

The

hydrogen sector, starting from methanisation,

should logically find its place in the near

future.

http://www.innovalor.fr/biogaz-biomethane.htm

|

|

|

Another

implementation of the GASWASH process for

the purification of biogas is possible according

to this scheme according to the current methods:

|

| |

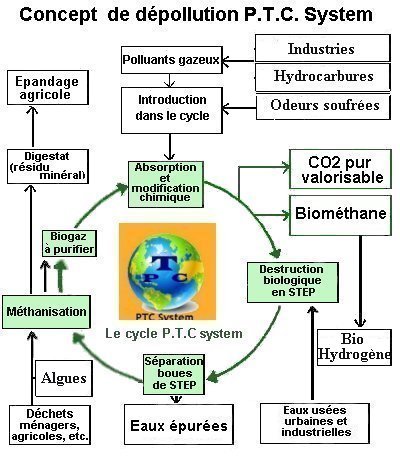

The

sustainable phase-out of pollutants

The

P.T.C. system loop

|

|

This

system is currently the only known system

for the long-term elimination of CO2 and which

can be recycled in

the industrial sector.

In a period particularly favorable to the

development of alternative energies to fossil

resources, the prospect of integrating biogas

into the French energy landscape is of political,

economic and environmental interest.

Indeed, the valorisation of domestic, industrial

and agricultural organic residues or the treatment

of wastewater satisfies the notions of sustainable

development and renewable energy, clearly

explained in the recent commitments and international

agreements. The environmental impact of the

implementation of biogas recovery schemes

results in a significant reduction in the

greenhouse gases discharged.

Recent

fluctuations in the costs of importing fossil

fuels have also positively influenced the

renewed economic interest in the production

of energy from biogas, whether directly in

the form of high purity methane gas Or in

the form of electricity.

The

cost of biomethane completely purified by

the GASWASH process is 0,054 € /kWh. When

the cost price in competing systems is around

0.15 €/kWh.

The GASWASH process. Allows a cost of production

of biomethane 3 times cheaper than the competition

and thus makes it possible to reduce the cost

difference between the methane of fossil origin

and the biomethane to incorporate it in the

network.

On the other hand, GASWASH technology allows

an extremely simple biogas purification equipment

whose investment cost is inconsistent with

the existing processes.

|

|

The P.T.C. system is part of this new concept

of purification / decontamination

The P.T.C. system is part of this new concept

of purification / decontamination

|

Innovalor

is looking for a partner or associate for

P.T.C. System and the DAVID and GASWASH processes

To make an offer

|

|