|

Example of treatment of a mixture of

pollutants in industry

Example of treatment of a mixture of

pollutants in industry

This

innovative "One-pot" process consists in capturing gaseous

pollutants in a physicochemical treatment whose liquid

effluents are subsequently digested by the aerobic bio-purification

process in the treatment plant.

(A)

Simultaneous

process of absorption (capture) and organic chemical

modification of Volatile Organic Compounds (organic

and inorganic).

This operation is carried out in a single operation

on a collection installation by physico-chemical washing.

(B)

The final destruction of the capture

products after the simultaneous process of absorption

and chemical modification

This ultimate operation (B) is carried out in a biological

treatment plant.

The organic compounds present and formed During the

condensation reaction are digested by the process of

natural aerobic bio-purification of the purification

plant.

The

originality of the process resides firstly in the choice

of the reagent which combines with the pollutants to

be treated and secondly in the final natural destruction

in the wastewater treatment plant that does not generate

any new gaseous pollution.

The example below describes the

treatment of a mixture of pollutants in a single operation

The example below describes the

treatment of a mixture of pollutants in a single operation

A

gas scrubbing column joins the vents of three "pilot"

reactors in chemical industry:

- Reactor

1 - Synthesis of an Acid Chloride

-

Reactor 2 - Synthesis of methyl ethyl sulfide

- Reactor

3 - Decarboxylation of an Acid

|

The

gaseous and volatile pollutants are composed of:

- SO2

(sulfur dioxide) 6,418 mg/m3

- HCl

(hydrochloric acid) 3 810 mg/m3

- Traces

of dichlorethane (solvent)

- Traces

of SOCl2 (thionyl chloride)

- CH3-SH

(methylmercaptan) 615 mg/m3

- C2H5-SH

(ethylmercaptan) 5 810 mg/m3

- H2S

(hydrogen sulfide) 4 000 mg/m3

- CO2

(carbon dioxide) 52 200 mg/m3

- Eventually

traces of alcohools

The

base and reagent quantities are calculated on

the worksheet

of flows and loads.

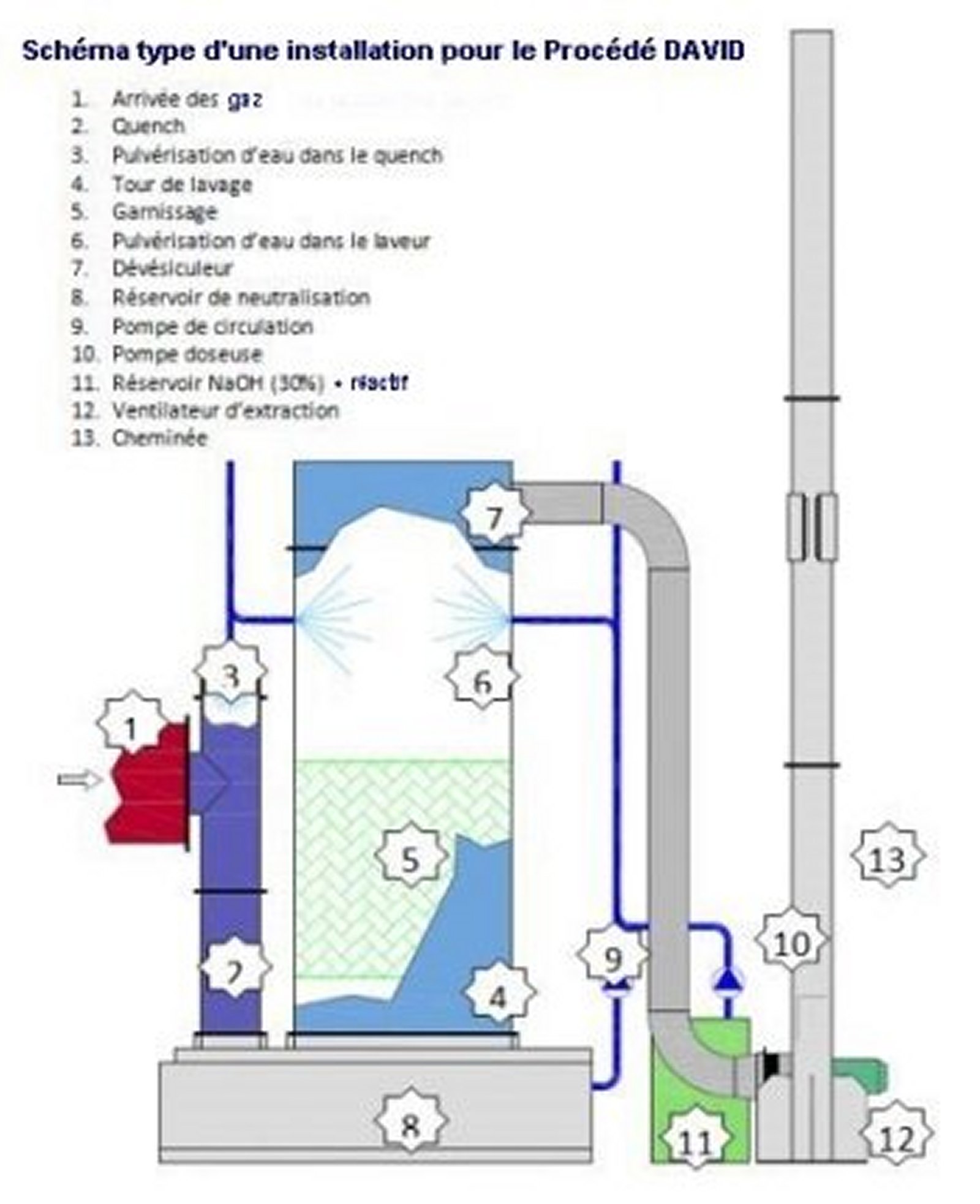

Equipment used:

Equipment used:

-

Absorption column 3000 liters (column + tank),

trays packing, demister outgoing air.

-

Fluid circulation pump adjustable from 0 to

25 m3/h.

- Adjustable

pollutant effluent gas supply valve from 0 to

1500 m3/h.H.

Operating load for a batch

operation:

Operating load for a batch

operation:

- Water:

400 L.

- 30%

soda: 2,010 kg

- 40%

reactive: 475 kg or 190 kg pure

|

Standard

equipment

|

Operating mode:

Operating mode:

In

the suction tank is charged the additional water determined

in the worksheet corresponding to 20 volumes of the

pure reagent and then in order the calculated amounts

of alkaline solution of potassium hydroxide, then the

40% solution of the reagent.

The reaction medium displays a pH value> 11.

The circulation pump is activated then the gas flow

valve is gradually released and controlled at the desired

flow rate.

The end of the reaction is determined and controlled

by pH <9.

The operations took place over a period of 10 hours

with a gas flow rate of 500 m3/h.

The end of the reaction is controlled by pH-metry (about

9-10), and the absence of H2S and mercaptans checked

with lead acetate paper and pH paper.

The

clear, colorless and odorless reaction medium is then

discharged to the plant's self-neutralization pit before

being discharged to the network to be subjected to the

aerobic bio-purification process in the treatment plant.

Results on the unfiltered reaction

medium before rejection to the biological station of

the site

Results on the unfiltered reaction

medium before rejection to the biological station of

the site

- pH

= 10.3;

- temperature

35 ° C

- COD:

298 mg/L

-

BOD5: 695 mg/L

In

this test, it is clear that for the destruction of sulfur

compounds, treatment with bleach would return 12 times

more expensive than treatment with the PTC system.

ClO2 or H2O2 treatments are even more expensive.

- This

example of chemistry treatment includes:

- Complete

elimination of sulfur compounds.

- Decarbonation

(complete elimination of CO2).

- Complete

elimination of hydrochloric acid.

- Complete

removal of traces of thionyl chloride.

- The

total elimination of the solvents present in the state

of traces.

Cost of treatment 627 €

whose:

Cost of treatment 627 €

whose:

- Soda:

503 €

- Reactive:

228 €

A

similar competitor treatment with bleach would have

cost € 1,030

For CO2 alone 1,582 liters of soda were consumed 30%

for € 395

The

flow calculation sheet to determine the quantities of

reagents:

The

flow calculation sheet to determine the quantities of

reagents:

See

also the examples of the DAVID Process - Odors

See

also the examples of the DAVID Process - Odors

|