|

Example for purification of a biogas

and obtaining pure biomethane

Example for purification of a biogas

and obtaining pure biomethane

This

innovative "One-pot" process consists in capturing gaseous

pollutants in a physicochemical treatment whose liquid

effluents are subsequently digested by the aerobic bio-purification

process in the treatment plant.

(A)

Simultaneous

process of absorption (capture) and organic chemical

modification of Volatile Organic Compounds (organic

and inorganic).

This operation is carried out in a single operation

on a collection installation by physicochemical washing.

(B) The

final destruction of the capture products after the

simultaneous process of absorption and chemical modification

This ultimate operation (B) is carried out in a biological

treatment plant. The organic compounds present and formed

During the condensation reaction are digested by the

process of natural aerobic bio-purification of the purification

plant.

The

originality of the process resides firstly in the choice

of the reagent which combines with the pollutants to

be treated and secondly in the final natural destruction

in the wastewater treatment plant that does not generate

any new gaseous pollution.

The

example below describes the treatment of 100 m3 of biogas

from the methanisation of sludge from an urban sewage

treatment plant. (test on a biogas line for sludge drying).

|

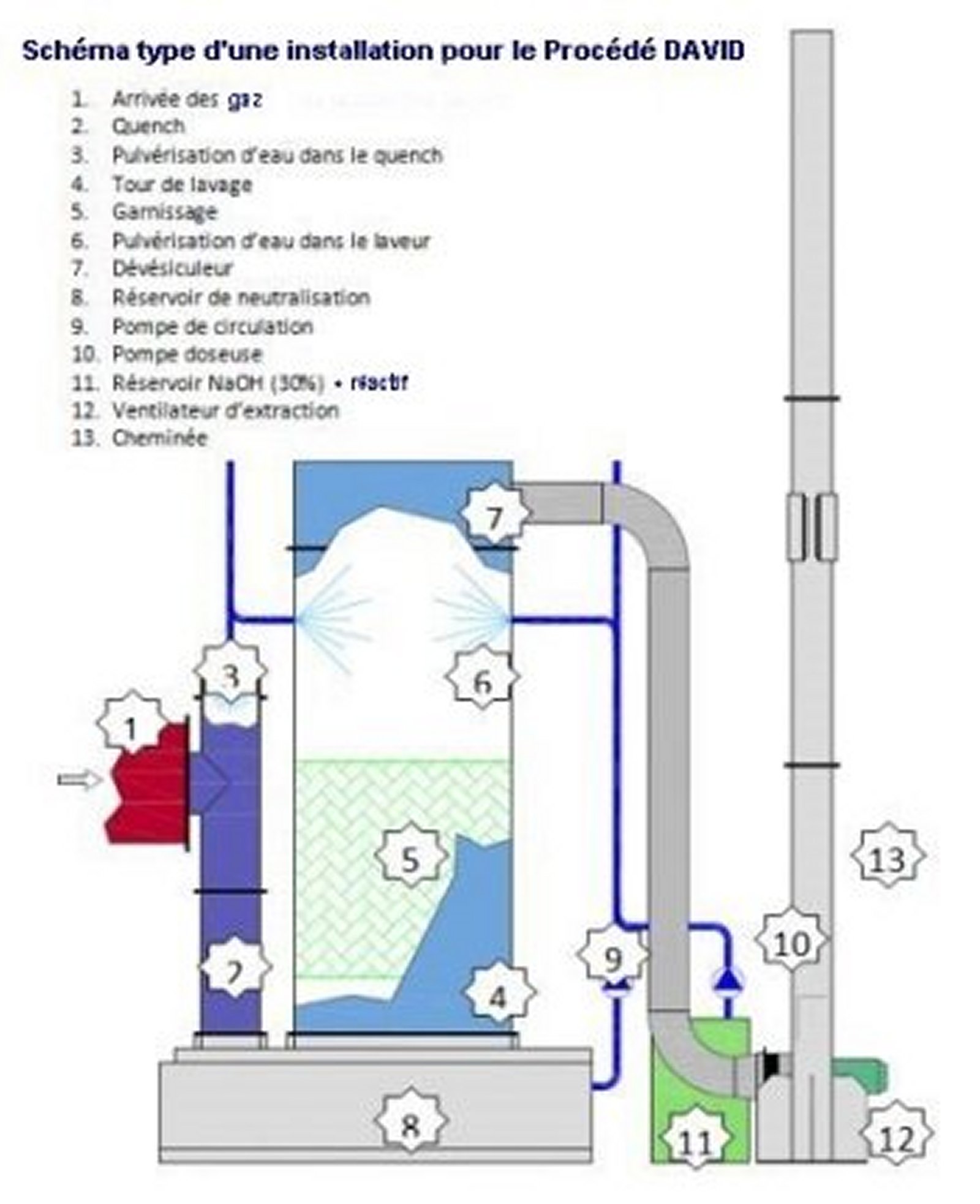

EQUIPMENT USED:

EQUIPMENT USED:

- Absorption

column 800 liters (column + tank), height: 3

m., base area: 0,28 m2 (diameter 60 cm), tray

lining, demister out of air.

-

Fluid circulation pump adjustable from 0 to

25 m3 / H.

- Adjustable

pollutant effluent gas supply valve from 0 to

1000 m3 / h.

AVERAGE COMPOSITION OF THE BIOGAS TO BE TREATED:

AVERAGE COMPOSITION OF THE BIOGAS TO BE TREATED:

Air

flow with a flow rate of 100 m3 / h. containing:

- Methane:

98.6% (98.6 m3)

- Miscellaneous

impurities (minority compounds): 0.4% (0.4 m3)

of which:

-

H2S: 10.618 mg / m3

- Mercaptans:

207 mg / m3 (Ethanethiol, methanethiol,

propane and butanethiol)

- Eventually

traces of siloxanes

The

base and reagent quantities are calculated from

the attached spreadsheet.

|

Matériel

type

|

OPERATIVE

CHARGE FOR DEMONSTRATION

OPERATIVE

CHARGE FOR DEMONSTRATION

-

Water: 400 L.

- 30%

soda:

33.5 kg

- 40%

reactive: 36.9 kg

VALIDATION

OF THE DEMONSTRATION OF TREATMENT

VALIDATION

OF THE DEMONSTRATION OF TREATMENT

This demonstration allowed an expected run time of 4

hours.

During this period of operation, regular checks of the

effectiveness verified the absence of H2S at the exit

of the industrial installation in place.

Results:

Absence of H2S validated at the column exit.

Cost

materials of the treatment: 26 € for the 4 h. Operating.

By way of comparison, a conventional treatment with

bleach would have cost 127 €

The

operation was carried out over a period of 4 hours with

a gas flow rate of 100 m3 / h.

The end of the reaction is controlled by pH-metry (about

pH = 9) and the absence of H2S verified with lead acetate

paper. The reaction medium is colorless and odorless.

CONCLUSIONS

OF THE DEMONSTRATION

CONCLUSIONS

OF THE DEMONSTRATION

Total

elimination of H2S and mercaptans during a 4 hr operating

period.

In this test, it is clear that for the destruction of

sulfur impurities, treatment with bleach is 2.5 times

more expensive than treatment with the GASWASH process.

- This

example of biogas treatment includes:

- Complete

elimination of H2S and mercaptans.

- Lowering

the 4% water of methanation to 40 ° C. (1 to 1.5%)

- Total

elimination of siloxanes and organochlorines or fluorinated

if present in trace amounts.

In this example, the GASWASH system was used to purify

100 m3 of biogas, which supplied 98 m3 of pure biomethane

but also of H2S and mercaptans.

TREATMENT

REVIEW

TREATMENT

REVIEW

The

98 m 3 of methane obtained with purity greater than

98.5% (biomethane) obtained can be used as an energy

source or as a precursor for the manufacture of biohydrogen,

for example with the VABHYOGAZ process.

Cost

for treatment with the GASWASH process:

Treatment

of 100 m3 of biogas: 26 € Either for a production of

98 m3 of methane for: 0,265 € / m3 or 2,68 cts. € /

kWh

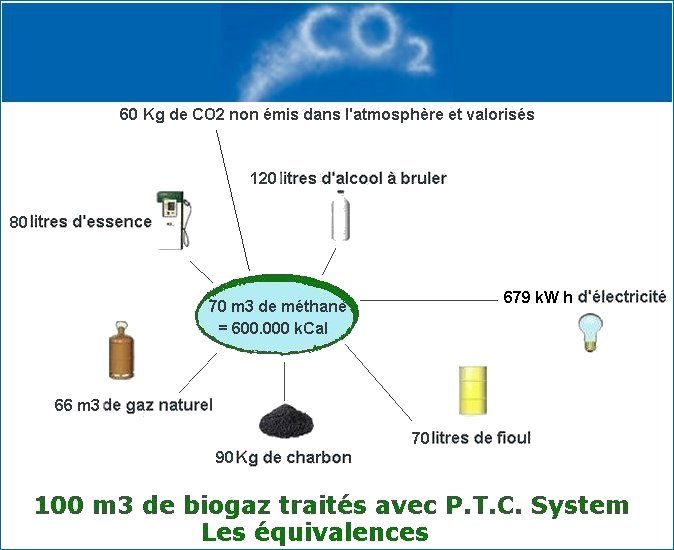

ANNEXE

ANNEXE

Energy equivalence

Energy equivalence

See

also the examples of the DAVID Process - Odors

See

also the examples of the DAVID Process - Odors

|